Soft Seal Gear Flanged Operated Ball Valve 2 Inch CF8M Material JIS10K

- Model Number:

- CX-2PC-CBV003

- Minimum Order Quantity:

- 1PC

- Prices:

- Negotiable

- Packaging Details:

- Plywood case

- Delivery Time:

- depends on the qty of order

- Payment Terms:

- L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Supply Ability:

- 10,000pcs per month

- Place of Origin:

- WENZHOU,CHINA

- Certification:

- API,ISO,CE

Detailed Product Description

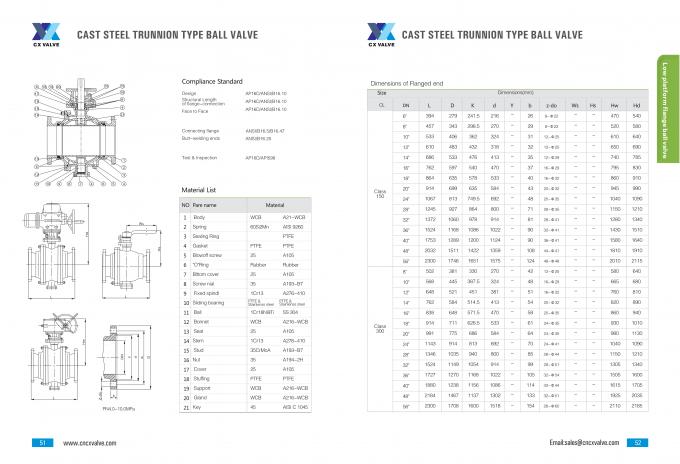

| Body Material: | Stainless Steel | Power: | Worm Gear |

|---|---|---|---|

| Pressure: | PN16/PN25/PN40,ANSI150LB,300LB,JIS10K,20K | Connection: | Flange |

| Structure: | Trunnion Ball Valve | Material: | Stainless Steel |

| High Light: | reducer port ball valve , trunnion ball valve | ||

Gear Operated Trunnion Mounted Ball Valve,CF8M Material, Soft Seal,Flanged,Fire safe,JIS10K

Specifications

- Available in sizes 2 " - 56 "

- Available in PN16~PN420,CLASS:150LB~2500LB,JIS10K/20K

- Superior flow with unique contoured ball design

- Full port,Reducer Port

- Available with Pneumatic, Electric, Gear or Lever Actuation

- Industries: Oil & Gas, Marine, Refining, Geothermal, Power, Chemical, Pulp & Paper, Cryogenic, Mining/Steel

- Manufactured under a certified ISO 9001 quality system

Overview

The trunnion ball valve is a form of quarter-turn valve which uses a hollow, perforated and fixed/supported ball to control flow through it.

A trunnion mounted valve means that the ball is constrained by bearings and is only allowed to rotate, the majority of the hydraulic load to be supported by the System constraints, resulting in low bearing pressure and no shaft fatigue. The line pressure drives the upstream seat against the stationary ball so that the line pressure forces the upstream seat onto the ball to cause it to seal.

The mechanical anchoring of the ball absorbs the thrust from the line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure operating torque remains low. This is particularly advantageous when the ball valve is actuated because it reduces the size of the actuator and hence the overall costs of the valve actuation package.

Advantage

Trunnion ball design is the lower operating torque, ease of operation, minimized seat wear (Stem/ball isolation prevents side loading and wear of downstream seats improving performance and service life), superior sealing performance at both high and low pressure (a separate spring mechanism and upstream line pressure is used as the sealing against the stationary ball for low pressure and high pressure m applications).

The trunnion is available for all sizes and for all pressure classes but they are not suitable for throttling purposes.

Application

The trunnion ball valve is used for cutting or connecting the medium in various pipelines of class150-class2500 and pn16-pn320. It can be suitable for various media such as water, steam, oil, liquefied gas, natural gas, coal gas, nitric acid, acetic acid, oxidizing media, urea and etc. It is widely used in such industries as chemical industry, petroleum, natural gas, metallurgy and etc. The driving modes of the trunnion ball valve include worm and worm gear driving, manual driving, pneumatic driving and electric driving. The trunnion ball valves generally adopt flange connection, and butt-welding connection is also adopted. The seat can be soft seal seat or metal hard seal seat.