High Performance Electric Double Eccentric Butterfly Valve Water Media

- Minimum Order Quantity:

- 1PC

- Prices:

- Negotiable

- Packaging Details:

- Wooden Case

- Delivery Time:

- 7-30 work days

- Payment Terms:

- L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Supply Ability:

- 10000PCS/Mouth

- Place of Origin:

- WENZHOU,CHINA

- Certification:

- API ISO Ts CE

Detailed Product Description

| Media: | Water | Driving Mode: | Electric |

|---|---|---|---|

| Connection Form: | Flange | Structure: | Double-Eccentric Sealing |

| Valve Stem: | Normal | Work Pressure: | Low Pressure (Pn<1.6mpa) |

| Working Temperature: | Normal Temperature (-40°C | Material Of Seal Surface: | Metal Hard Sealed |

| Valve Body: | Casting | Standard: | API 609 |

| Application: | Industrial Usage, Water Industrial Usage, Household Usage | Body / Disc / Stem / Seat: | Wcb, 304, 316, C95800, C95500, C95400 |

| High Light: | flanged end butterfly valve , metal seal butterfly valve | ||

Flange Type Rubber Lined Double Flange Buttterfly Valve

CX Three eccentric butterfly valve series is the newly-developed long-life and energy-saving products. The sealing is metal to metal, which couldbe changed to be seal ring to metal, stainless steel plate and composite graphite to metal. Under the working condition of high temperature and high pressure, it still has a stable sealing performance. Our company adopts optimization design and new technology, so that the torque is small, gainning the point of energy-saving, labor-saving and reliable sealing performance, thus to ensure the high-reliability of corrosion-resistantance, stand fire and wear-resistantance. This product is widely used in petroleum, natural gas, piped gas and medicine, food industry, industrial environmental water treatment and shipping industry.

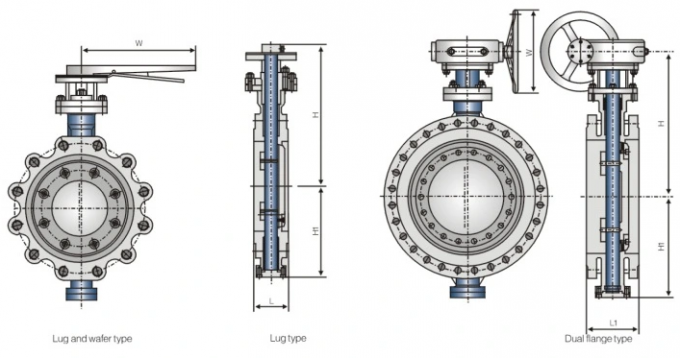

Figure :

- Wafer or Lug Style

- Cast Carbon, Stainless or Alloy Steel

- Other sizes and classes available on request

Design Features

- Upper and Lower Bearings to maximize valve life

- Integral ISO mounting pad for easy valve operation no bracket needed

- Each valve is shell and seat pressure tested per industry standard API 598

- Available in Wafer and Lug styles

- Seat Materials: Multiple seat materials available.